5 Signs Your Home Needs Foundation Repair

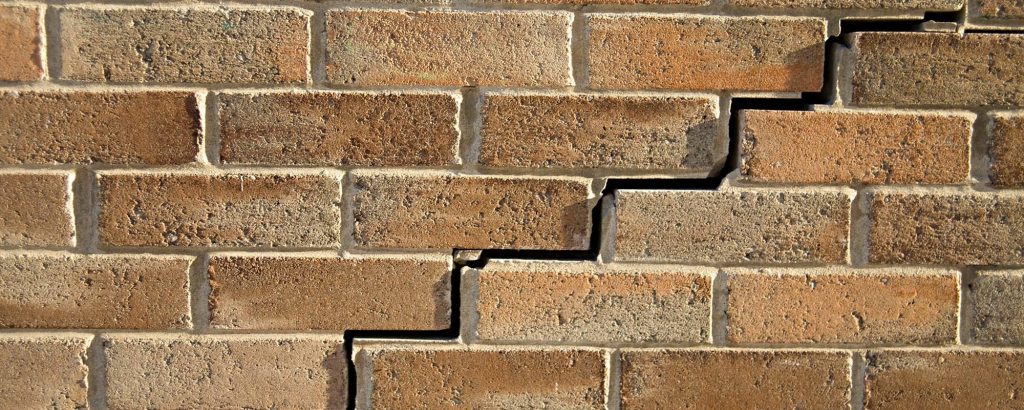

5 Signs Your Home Needs Foundation Repair You love your home, but even if it looks perfect from the outside, there may be underlying issues that need to be addressed. For example, when the foundation needs repair, you may not notice the signs until it is too late....